OEM manufacturer Temp Calibration - PR340 Standard platinum resistance annealing furnace – Panran

OEM manufacturer Temp Calibration - PR340 Standard platinum resistance annealing furnace – Panran Detail:

Overview:

PR340 standard platinum resistance annealing furnace is a special equipment for standard platinum resistance annealing. General use temperature is 100 ~ 700 ° C. The furnace is a professional temperature measurement department and other departments such as metallurgy, machinery, chemical, electric power, scientific research, etc., which are indispensable equipment for thermal resistance verification.

PR340 The SPRT annealing furnace integrates the furnace body and temperature control, and has a reasonable structure and beautiful appearance. The utility model has the advantages of fast heating speed, high temperature control precision, good heat preservation performance, uniform temperature field and convenient use and maintenance. Its various performance indicators are in line with the requirements of the national metrological verification regulations.

PR340 The control part of the SPRT annealing furnace is composed of AI artificial intelligence regulator, thyristor power module and XMB5000 display instrument.

PR340 The temperature control part of the SPRT annealing furnace is composed of AI artificial intelligence regulator, thyristor actuator and the like. The temperature of the test furnace is manually set by the AI artificial intelligence regulator. The control parameters of the AI artificial intelligence regulator are generally determined by self-tuning (also allowed manually). When the temperature signal input of the calibration furnace is compared with the set value, the AI artificial intelligence regulator can automatically output the thyristor trigger pulse to push the thyristor actuator. In order to achieve accurate temperature control purposes.

The XMB5000 display is mainly used for display and over-limit alarm functions to prevent the furnace temperature from exceeding the set temperature and double insurance.

The furnace body can also be offered separately.

Technical parameters:

1. Temperature range:100~700℃

2. Dimensions: 750×550×410(H×L×W)(mm)

3. Hole No.:7holes

4. Insert depth:about 400mm

5. Temperature control stability:≤±0.5℃/15min

6. Vertical temperature field: the temperature difference within the working area of 60mm is not more than 1 °C

7. Power supply:50HZ 220V±10%

8. Maximum heating current: 10A

Installation wiring:

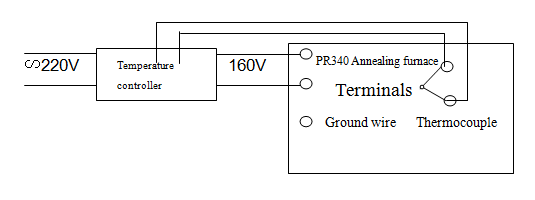

PR340 The SPRT annealing furnace can be placed in any place in the working room and should be placed smoothly. Please connect the power cord correctly as shown below:

Use and precautions:

1. For the operation of the SPRT annealing furnace in the use of AI artificial intelligence regulator, please refer to the "AI Artificial Intelligence Industrial Regulator Instruction Manual".

2. SPRT annealing furnace is precisely temperature controlled using an AI artificial intelligence regulator. When the furnace is shipped from the factory, the parameters of the AI artificial intelligence regulator have been adjusted, and the user does not need to adjust the parameters.

3. If the furnace temperature control is not ideal, please refer to the AI artificial intelligence regulator instruction manual, set the CtrL parameter to 2 to start the auto-tuning function of the AI artificial intelligence regulator, and re-adjust the temperature control parameters.

4. PR340 After plugging the power plug of the SPRT annealing furnace into the power socket, first turn on the power switch in the chassis, set the AI artificial intelligence regulator SV (set value) to the verification temperature, turn on the panel temperature rise switch, and the furnace will automatically heat up to give Value.

5. The standard platinum resistance thermometer annealing temperature should be determined according to the upper limit temperature used. Annealing at 660 ° C is required for use above 600 ° C, annealing at 600 ° C is required for use above 400 ° C, and annealing at 450 ° C is required for use below 400 ° C.

When the standard platinum resistance thermometer is annealed, the standard platinum resistance thermometer should be placed in the annealing furnace after the annealing furnace temperature is stable.

Full set in package

When the user unpacks the product, it should include the following 5 parts.

1. One PR340 standard platinum resistance annealing furnace

2. Product certificate

3. PR340 standard platinum resistance annealing furnace instruction manual

4. AI artificial intelligence regulator instruction manual

5. XMB5000 display instrument manual

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for OEM manufacturer Temp Calibration - PR340 Standard platinum resistance annealing furnace – Panran , The product will supply to all over the world, such as: moldova, USA, Guatemala, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.