PR330 Thermocouple Calibration Furnace with Multiple Calorifiers

Overview:

The verification furnace or calibration furnace isan important part of the medium and high temperature traceability system. In general,the traditional verification furnace orcalibration furnace is a horizontal electric furnace with simple structure. The temperature uniformity of the effective working area of the furnace can not be well controlled, and the temperature uniformity of the furnace is prone to deviation after the furnace has been used for a long time.Even if the temperatureuniformityof thefurnace is improved to a certain extent by adding metal thermostatic block, its overall technical performance is still not ideal, which is the main source of uncertainty in the process of thermocouple verification and calibration.Therefore, the traditional verification furnaceor calibration furnace cannot meet the requirements of high-precision temperature traceability in terms of structure. PR330 series calibration furnace with multiple calorifiersadopts a subversive design scheme from the internal structure to the control method, and has made a qualitative leap in key technical parameters.

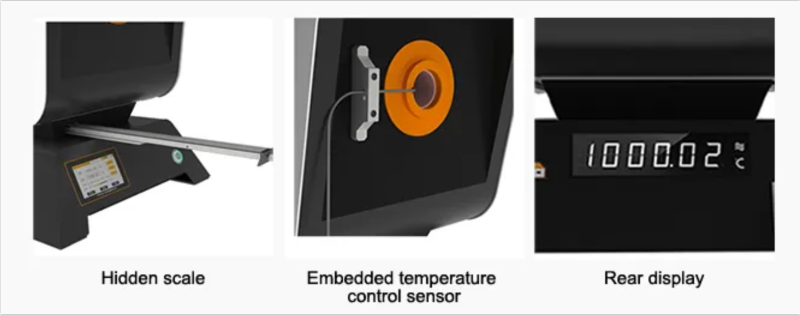

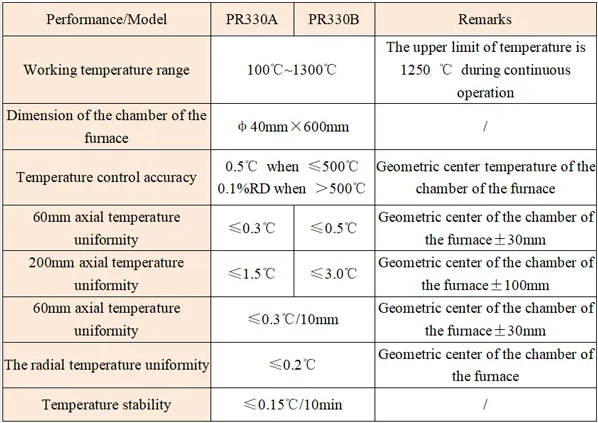

PR330 series calibration furnace with multiple calorifiers adoptsinnovative technologies such as controlling with multiple calorifiers, DC heating, load balancing, active heat dissipation, and embedded temperature control sensor to extend its working temperature to 100°C~1300°C. With excellent temperature uniformity and temperature stability covering the entire temperature range, the calibration furnacegreatly reduces the uncertainty in the temperature traceability process. In addition, thecalibration furnace possessespowerful human interface function, communication function, and many humanized designs including front and rear dual display screens and hidden scales.

Features:

■ Characteristics of wide temperature uniformity over the entire temperature range

Adoptingtheheating technologywith multiple calorifiers, the power distribution ratio of different parts of the furnace body heating cavity can be calculated in real time according to the current set temperature and heat dissipation conditions, and the ideal temperature uniformity can be achieved at any temperature point without the thermostatic block.

■ Wider working temperature range

With many new designs in the furnace structure and materials, the working temperature range of the calibration furnace is extended to 100 ℃ ~ 1300 ℃. The calibration furnace can be operated at 1300℃ for a short time or 1250℃ for a long time. The minimum control temperature can be as low as 100 ℃, which further widens the temperature calibration range of thermocouple.

■ The temperature stability is better than 0.15 ℃ / 10min

Integrated new generation PR2601 master controller of PANRAN, with 0.01 level of electrical measurement accuracy, and according to the control requirements of the calibration furnace, the calibration furnace has made targeted optimizations in terms of measurement speed, reading noise, control logic. And its full-range temperature stability is better than 0.15℃/10min.

■ Embedded temperature control thermocouple

In order to make the process of placing the calibrated sensor more convenient, a detachable temperature control thermocouple is embedded in the inner wall of the heating chamber, which will neither affect the insertion of other sensors nor adversely affect the temperature control process.

■ High security

The power components of PR330 series multi-zone temperature calibration furnaces adopt full DC drive, which can avoid the disturbance caused by electric leakage at high temperature and other high voltage safety hazards from the source. The shell has an independent heat dissipation air duct, which can effectively reduce the temperature of the furnace surface when working at high temperature and avoid scalding caused by misoperation.

■ Load balancing function

By adding an extra thermocouple to monitor the change of axial temperature uniformity in the heating chamber in real time, PR330 series multi-zone temperature calibration furnaces can adjust the power distribution ratio in real time to offset the influence of load insertion and maintain the optimal axial temperature uniformity, so as to meet the higher requirements of calibration.

■ Powerful software and hardware function

The front touch screen can display general measurement and control parameters, and can perform operations such as timing switch, temperature stability setting, and WIFI setting. In order to facilitate the observation of real-time temperature from multiple angles, a secondary display with stability indication is also installed at the rear of the calibration furnace.

PR9149C oil-water separator